Many people, especially those working in technical areas, have at least heard of kanban. Ask them what kanban is and you are likely to get an answer of the sort, “Isn’t it a visual method for managing projects?”1 Well, that’s like saying that Michelangelo’s Sistine Chapel ceiling is a decoration. It’s true, but it is very far from capturing its essence.

If you are an experienced kanban coach or professional, you will probably find the following remarks to be trivial. But suppose you have simply heard of kanban, without having gained practical experience. Or suppose you do use kanban and you are happy with its definition as a visual management method. I would suggest that the principle benefits of kanban come from something other than visualizing your work on a card board.

Visualization of work is a good start

For some people, the maturity level of their organization’s use of kanban gives the impression that kanban is just a visual management method. For, in fact, most people first perceive kanban as the card board used to visualize their work.

True, this visualization greatly benefits most organizations. You frequently hear remarks such as, “We have never really seen all the different types of work we do before using this card board!” Visualization assembles for us the data set corresponding to the work in the offing, in progress and completed. The more that data set is but a small selection of your tasks or subject to selection bias, the more your decisions based on that data will be ill advised. The poorer will your system be for managing the flow of work. In fact, the visualization of your work in the form of a card board confirms in a very intuitive way that you are truly attempting to manage the flow of all your work.

Think of what happens in many traditionally managed projects. The project manager attempts to create a detailed plan of all the tasks required to complete the project. But, when the project falls behind and the project manager attempts to understand the causes of delay and blockage, he or she often discovers that people perform many tasks for the project that were not planned at all. Or, it turns out that resources perform more work on non-project activities than initially planned.

So, it is important to be aware of all the work being done by a team. Visualization on a board is one method to help achieve this goal.

A question of maturity

So, you are doing a good job of visualizing your work. Great! But how are you using that visualization to improve the flow of your work? In many organizations, you do little or nothing in that regard.

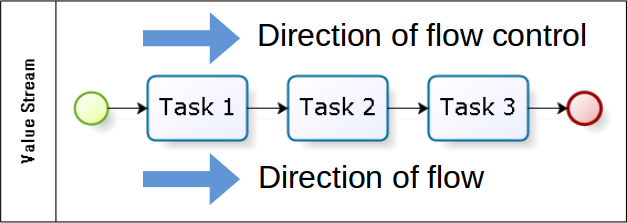

In some cases, your team recognizes that the kanban method comprises much more than visualization. But you are limited to the visualization practice simply because you are only on your first steps of the kanban journey. Good management of the flow of work requires that people become accustomed to creating cards for their tasks and moving those cards from value stream phase to value stream phase (see Fig. 1). Without this basic tracking of work, all the rest of workflow management is extremely difficult to implement effectively.

In other words, the team is on the path to improving its work flow using kanban, but is at a low level of maturity. That’s fine, so long as the team does not stagnate at that level.

A question of misconception

On the other hand, many teams or individuals stop at visualization due to various misconceptions about kanban. Here are three common misconceptions that I will examine in more detail:

- Kanban boards are necessary to work according to the kanban method

- Kanban is a project management method

- Kanban is a view on your ticketing tool queues

Misconception #1 - Kanban boards are necessary

As useful as they are for knowledge work, card boards are not essential to the use of kanban. Unfortunately, many organizations believe that kanban is nothing more more than the visualization of work on a board. In fact, using a card board to facilitate the management of flow is an invention that expanded the use of kanban from managing manufacturing to managing the flow of knowledge work, too. In the Toyota Production System, where kanban was invented, kanban cards are not displayed on a board at all!2 Kanban cards exist, but they are used with the batches of materials used to build automobiles.

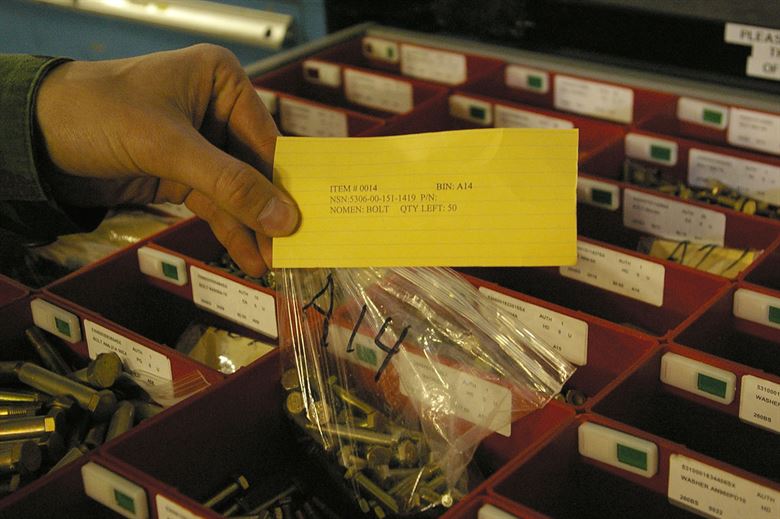

Cards are not on boards for sales and manufacturing

If you use kanban to manage your stock in a retail store, you are likely to put kanban cards on the shelves with the merchandise. They signal to stock managers that it is time to fetch more goods from the stock room. You are likely to see a part number, a quantity to resupply and the location from which the parts should be fetched.

If you use kanban to manage the manufacture of physical goods, you probably keep those cards in the batches of materials used as input to each processing station in the manufacturing process. They signal the frequency of the resupply of input materials at each station in the manufacturing process.

Card boards are used for knowledge work

However, knowledge work, unlike retail sales and manufacturing, manipulates data, ideas and knowledge, rather than tangible materials. You cannot attach a physical kanban card to an intangible concept. Data and information are hidden from sight. They reside in our brains or in the memory of computers. There is no easy way to position kanban cards in either place (given existing technology).

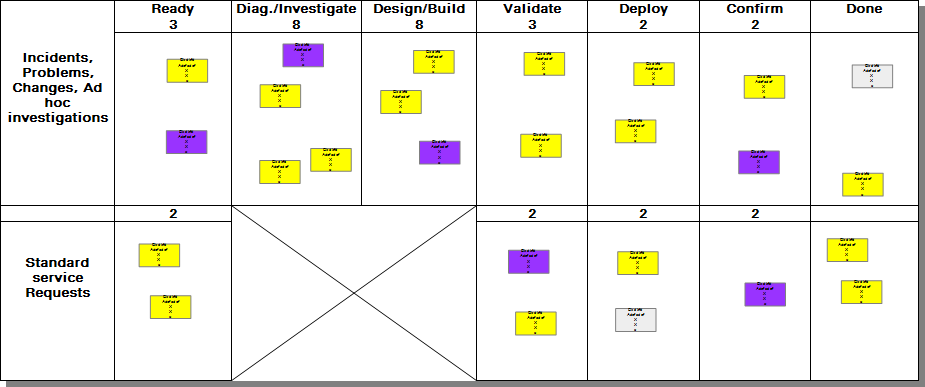

The kanban board allows us to virtualize the value stream we use, displaying it as columns and rows in a table. The kanban cards symbolize batches of work (work items). They are positioned in the appropriate cells of that table, thereby symbolizing, the status of each work item in the value stream.

Are kanban card boards necessary for using kanban for knowledge work? In principle, they are not. However, whether that board is a physical board or a virtual board displayed using software, most organizations find them to be the easiest, most intuitive way to visualize their work. But the essence of kanban is not in the board itself. It is in the techniques used to manage the flow of work—that work made visible via the card board.

Think of a kanban board as a form of virtual telemetry used to manage the flow of work. It is like a thermometer used to display the current temperature. Measuring the temperature is great, but completely valueless unless you make decisions based on those readings. Visualizing work is fine, but only insofar as it gives you the data you need to make decisions about managing the flow of your work.

Is a card board the best way to visualize work? Many organizations find this to be true. Is a card board the only way to visualize work? That is surely not the case. But what else is there? I have elsewhere discussed the use of Marey charts and Sankey diagrams. In the spirit of kanban, teams should experiment collaboratively to find visualization techniques that best meet their own needs, culture and experience.

Misconception #2 - Kanban is a project management method

False! This misconception is a case of putting the cart before the horse. Kanban is a flow management method for any form of work. Since some work is organized in projects, the flow of work in a project can be managed using kanban. However, the overwhelming amount of work managed using kanban is not project work (unless, of course, you were led to believe that kanban is only for managing projects).

In fact, organizational units should use kanban to manage all their work, whether in a project or not. If you try to use kanban to manage only the work done in a project, ignoring what the project team members do out of that project, kanban is likely to be a relatively ineffective method. You might get some benefit from it, but nothing like its true potential.

Misconception #3 - Kanban is a view on your ticketing tool queues

Today, many ticketing tool products are jumping on the kanban bandwagon. They add views of ticket queues arranged in a matrix, just as in a kanban board. And so, they proudly declare that they support kanban, or even that they allow you to implement kanban in your organization.

As we know since the work of Marshall McLuhan, we in the electronic age tend to view the world via our tools. So we can understand why you might believe that you are using kanban if your ticketing tool tells you so. I hope you will excuse my extreme skepticism of such claims.

There is a fundamental difference between the management of flow that most ticketing tools support and the kanban method. Ticketing tools generally are based on a push method of managing the flow of work. Kanban, on the other hand, implements a pull method of managing flow. The easiest way to illustrate the difference is to contrast the older business model for American automobile manufacturers with the business model of Toyota, when using the Toyota Production System.

In the older American model, the basic concept was to first build the cars and then figure out how to sell them. Since predicting how many cars will be sold is a very tricky business, there was often a big mismatch, resulting in lost opportunities, capital tied up in inventory and huge amounts of waste. This is a push model. Work is triggered by the plans of the managers.

In the pull model, work is triggered by the needs of the customers. A customer places an order; the order is fulfilled from stock. The size of the stock is strictly limited so as not to tie up capital in a risky way. But, since a slot is opened for more stock, another automobile is manufactured and sent to stock. And this triggers, in turn, the resupply of the raw materials needed to build a new automobile. In other words, each step in the production process is triggered by downstream events. In the push model each step is triggered by upstream events.

So, is Kanban a visual management method?

![]() The article Is Kanban a Visual Management Method? by Robert S. Falkowitz, including all its contents, is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The article Is Kanban a Visual Management Method? by Robert S. Falkowitz, including all its contents, is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Bibliography

[a] Ohno, Taichi, Toyota Production System: Beyond Large-Scale Production, Productivity Press 1988.

[b] Anderson, David J., KANBAN. Successful Evolutionary Change for Your Technology Business. Blue Hole Press. 2010.

Notes

Credits

Unless otherwise indicated here, the diagrams are the work of the author.

Fig. 3: By Karen Abeyasekere, U.S. Air Force – This Image was released by the United States Air Force with the ID 080527-F-0000A-001[1], Public Domain, https://commons.wikimedia.org/w/index.php?curid=74965372

Fig. 4: From the film Annie Hall.

Fig. 7: The “fish on a bicycle” image is downloaded from https://www.fishonabike.com/ © Adam Sobot

Leave a Reply